API 5CT Tubing

Introduction

Specification

Application

Specification: OD: 40.26mm ~ 114.3mm

WT: 3.18mm ~ 16mm

LENGTH: R1, R2, R3

Standard & Grade: API 5CT J55/K55/N80/C75/L80/C90/T95/Q125

Process Type: Seamless (SMLS), Electric Resistance Welded (ERW)

End: Beveled, Square Cut, With NUE/EUE Connection

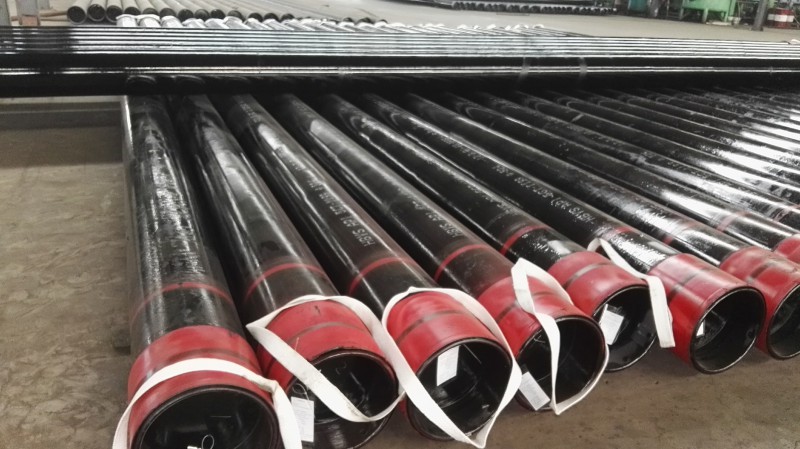

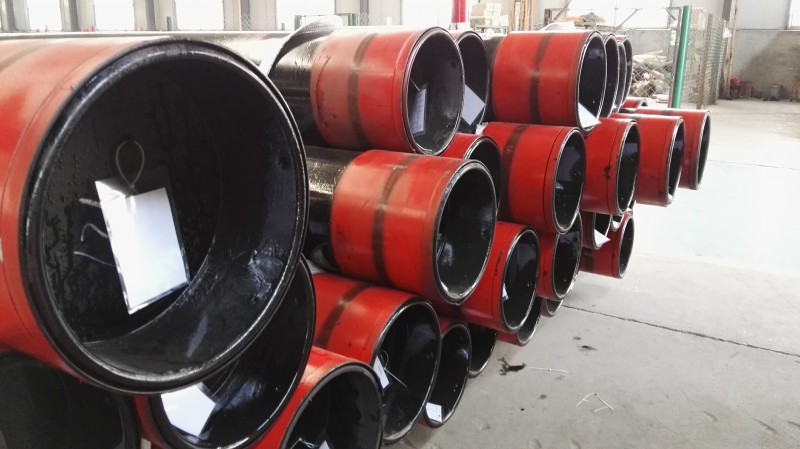

Surface: Anti-corrosion Water Based Paint

Packing: Protection Caps in both end, Waterproof Paper Wrapped, Two Tags

Tolerance

| Pipe Types | Pipe Size (mm) | Tolerances | |

| Hot Rolled | OD | ≤159 | ±1.0% |

| >159 | ±1.20% | ||

| WT | ≤20 | ±12.5% | |

| >20 | ±10.0% | ||

| Cold Drawn | OD | ≤30 | ±0.20mm |

| 30-50 | ±0.30mm | ||

| >50 | ±0.8% | ||

| WT | ≤3 | +12% -10% | |

| >3 | ±10% | ||

Chemical Composition & Mechanical Properties

| Grade | Chemical Composition | Mechanical Properties | |||||||||

| C | Mn | Si | Cr | Mo | Ni | S | P | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | |

| 10 | 0.07-0.14 | 0.35-0.65 | 0.17-0.37 | ≤0.15 | - | ≤0.25 | ≤0.035 | ≤0.035 | 330-490 | ≥205 | ≥24 |

| 20 | 0.17-0.24 | 0.35-0.65 | 0.17-0.37 | ≤0.25 | - | ≤0.25 | ≤0.035 | ≤0.035 | 410-550 | ≥245 | ≥21 |

| 12CrMo | 0.08-0.15 | 0.40-0.70 | 0.17-0.37 | 0.40-0.70 | 0.40-0.55 | ≤0.30 | ≤0.035 | ≤0.035 | 410-560 | ≥205 | ≥21 |

| 15CrMo | 0.12-0.18 | 0.40-0.70 | 0.17-0.37 | 0.80-1.10 | 0.40-0.55 | ≤0.30 | ≤0.035 | ≤0.035 | 440-640 | ≥235 | ≥21 |

| 1Cr2Mo | ≤0.15 | 0.30-0.60 | 0.50-1.00 | 2.15-2.85 | 0.40-0.65 | - | ≤0.035 | ≤0.035 | ≥390 | ≥175 | ≥22 |

| 1Cr5Mo | ≤0.15 | ≤0.60 | ≤0.60 | 4.00-6.00 | 0.45-0.60 | ≤0.60 | ≤0.035 | ≤0.035 | ≥390 | ≥195 | ≥22 |

Used for the transmission of oil & gas